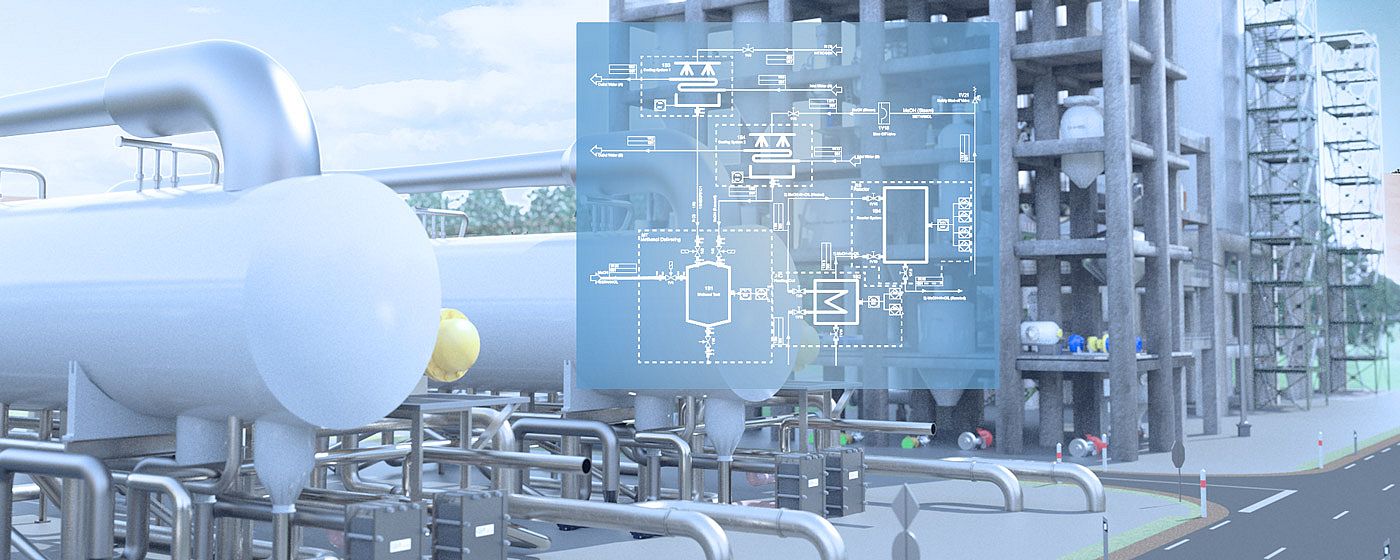

Intelligent and simultaneous design with the Engineering Base platform means: convenient, location-independent access to a central data model, rule-compliant P&IDs and working with "smart" pipes. In short: highest efficiency, safety and quality.

The challenge

Projects in the process industry are characterized by high complexity of plants and great time and cost pressure. The crucial task is to keep track of the enormous amounts of data in the engineering, so that all the trades and experts involved in the process can cooperate seamlessly - especially if they are situated at different locations.

The P&ID resulting from the process design is the starting point for all other engineering disciplines and therefore needs to be fully up to date and reliable. Every change must be clearly recognizable and comprehensible to everyone else.

The solution

A basis for the digital plant model

For a collaborative, cross-discipline and end-to-end plant design process, AUCOTEC offers the database-based, object-oriented Engineering Base (EB) platform. It combines process design, FEED, instrumentation & control, electrical, cause & effect and automation support in a unique solution.

Central process design

The process design starts with the construction of a rough PFD (Process Flow Diagram) or the result of the FEED phase (Front End Engineering Design), i.e. the "winner scenario", which gave the best result in the simulation. The data centring of EB ensures that even globally distributed planning teams always stay up to date with the plant documentation.

Smart pipes

EB works on the basis of rule-based P&ID. Rules that e.g. apply to a particular pipeline, automatically affect all devices installed in this line. In addition, the piping representation can be supplemented with additional information such as flow direction, media flowing through, temperatures and pressures.

Your benefits

Pipe class-based workflow, rule-based work: EB's central data model offers designers maximum efficiency, safety and quality:

- Overarching synergy and unique consistency in process design

- Convenient, compliant P&ID creation

- Automatic error detection and marking

- Automatic pipe class component selection

- Simple line segmentation

- Quick overview of "smart" pipes with all the background information

- Automatic creation of bills of material